Understanding Low-Speed Swept Path

As vehicles get longer to increase the operational efficiency of Australia’s road transport industry, one of the points that an operator must consider is how much these longer vehicles will cut in during a turn. Excessive cut-in may restrict a vehicle’s ability to access certain roads.

The amount of cut-in that a vehicle causes is measured by the Performance Based Standards scheme (PBS) under the Low-Speed Swept Path (LSSP) standard.

What is LSSP?

LSSP is defined as the greatest distance between the innermost point and the outermost point of a vehicle during the 90-degree 12.5‑metre radius turn manoeuvre.

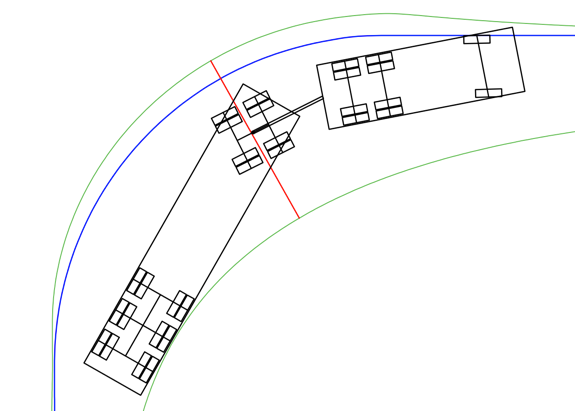

The diagram below illustrates a combination completing an LSSP manouevre.

The blue line shows the path of the outer steer tyre, the green lines show the extreme inner and outermost paths of the vehicle and the red line is where the maximum LSSP is achieved during the turn.

While LSSP is usually not a major concern for many common PBS combinations such as truck and dogs, it can often be a deciding factor in whether longer combinations can pass PBS standards.

A major factor in LSSP performance is the number of articulation points, with more articulation points being more favourable. The additional points allow the vehicle to more closely ‘fit’ the turning path. For example, A-doubles have three articulation points, while B-doubles have only two. As a result, B-doubles tend to have worse LSSP performance than an A-double of the same overall length.

How can I optimise for LSSP?

Aside from decreasing the distance between the king pins and axle groups of your vehicles, what else can be done to improve LSSP?

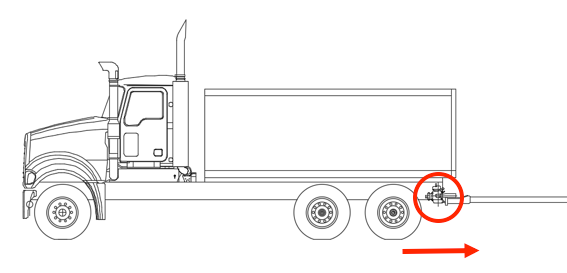

Reduce the fifth wheel lead, or increase the coupling rear overhang.

Contrary to the general logic of ‘shorter is better for LSSP’, these changes will make your combination longer while also improving LSSP performance. Pushing the coupling point back causes the front of the next unit to move towards the outside of the turning path, reducing the cut-in caused by all the following trailers.

Reduce the front overhang of the prime mover or truck

The front overhang is the amount that the truck protrudes forward past the steer axle. Reducing this brings the outermost point from which LSSP is measured closer into the turning path. If decreasing the front overhang of the truck isn’t possible, then rounding off the corners can have the same effect, as these are usually one of the critical points for measuring LSSP.

Make the rear of an axle group steerable

A steerable rear axle can have a significant impact on the LSSP by effectively reducing the distance between the kingpin and the centre of the rear axle group. Increasing the axle group spread can further increase the positive impact of a rear steerable axle. Some particularly long vehicles will find that this is the only way to meet the PBS performance requirements, depending which PBS level they aim to achieve. As recently discussed, A-doubles that go beyond 30 metres in length will find it increasingly likely that they require the use of steerable rear axles to pass PBS.

Which option should I choose?

Unfortunately, there are always trade-offs when optimising a combination for one goal. While low speed manoeuvres may be improved by making one of the above changes, there is a tendency for these changes to have an unfavourable effect on the dynamic performance of the vehicle, or they may simply be impractical. Determining the optimal layout for your combination will always be a matter of balancing these trade-offs with respect to the priorities for what the combination must achieve in operation.

Contact Advantia if you would like to investigate PBS opportunities for your business.

Get more like this in your inbox

Subscribe to our Newsletter and never miss a post.