Suspension misconception

Contrary to what you may think, roll stiffness is not necessarily the most important consideration when comparing the vehicle dynamics effects of one suspension with those of another.

Roll stiffness is indeed important for some aspects of heavy vehicle stability, such as steady-state rollover threshold, because a higher roll stiffness reduces the amount of body roll for a given amount of lateral force acting on the body.

But what other aspects of a suspension’s design can affect a vehicle’s dynamic performance? Two other parameters are ‘roll centre height’ and ‘roll steer coefficient’. Depending on the situation, each of these parameters can have a critical impact on performance. Let’s take a look at each of these three parameters in turn.

“Two other parameters are ‘roll centre height’ and ‘roll steer coefficient’. Depending on the situation, each of these parameters can have a critical impact on performance. Let’s take a look at each of these three parameters in turn.”

Roll stiffness

Roll stiffness is the term used to describe a suspension’s resistance to body roll. It is expressed as the magnitude of the resisting moment developed per degree of body roll. If the moment is measured in Newton-metres, then the roll stiffness is expressed in Newton-metres per degree (N.m/deg). A higher value of roll stiffness means that a suspension is likely to result in less body roll during travel.

In a typical trailer air suspension, the resisting moment is developed partly by differential compression of the airbags but mostly by ‘auxiliary’ means including torsion of the axle beam, bending of the trailing arms and compression of the pivot bushes. A typical drive axle air suspension will rely less on axle beam and trailing arm distortions and more on dedicated anti-roll bars to provide the auxiliary roll stiffness. Either way, if the vehicle has an overturning moment acting on it, the amount of resultant body roll will depend on the amount of total roll stiffness in the suspension, being the sum of roll stiffness inherently derived from differential compression of the airbags and the additional auxiliary roll stiffness. Higher roll stiffness is generally better for vehicle dynamics.

Roll centre height

When a vehicle’s body leans to one side, it does so about an imaginary axis running along the vehicle’s centreline at some height above the ground. This axis is known as the roll centre, and its height is important. For simple suspensions the height of the roll centre can be determined by examining the suspension design. It is governed by the method by which lateral constraint is built into the suspension. Look for what is preventing the axle from moving sideways. For a trailer air suspension it is typically the trailing arm pivot bolts. For a drive axle suspension it is typically the V-shaped torque rod mounted between the chassis rails and the top of the axle housing. If there can be no lateral movement at a particular location in the suspension system, then that location must be the height of the roll centre. Any part of the body that is at a different height will move laterally by a small amount whenever the body leans to one side.

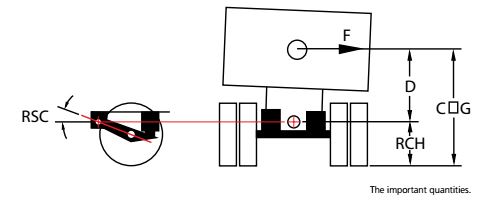

So why is roll centre height important? Take a look at the figure. You can see that a lower roll centre height (RCH) results in a larger lever arm (D) for any lateral force (F) acting on the body. That means that for the same lateral force, a lower roll centre height will result in a greater overturning moment, and therefore a greater amount of body roll, even if roll stiffness is the same. It follows that a suspension with a greater roll centre height is preferable from the perspective of body roll per unit of lateral force acting on the body.

Roll steer coefficient

Many suspensions have a characteristic known as roll steer. This is most easily described in the context of trailing arm air suspensions. Again, take a look at the figure. Imagine drawing a line from the centreline of the trailing arm pivot bolt through the centreline of the axle. If that line is at an angle to the horizontal, whenever the body leans to one side there will be a small amount of axle steer as the line increases in slope on one side of the vehicle and flattens out on the other. The ratio of resultant axle steer angle to body roll angle is the roll steer coefficient, and it can be derived from the angle of the pivot bolt to axle line.

In most cases the pivot bolt is higher than the axle, but it can be level with the axle or lower than the axle for low ride height suspensions. When the pivot bolt is higher than the axle, the effect of roll steer is generally to increase trailer sway in some dynamic manoeuvres.

“When the pivot bolt is higher than the axle, the effect of roll steer is generally to increase trailer sway in some dynamic manoeuvres.”

While lowering the pivot bolt height can result in decreased trailer sway in such manoeuvres, this also has the effect of lowering the roll centre height, which can decrease other aspects of vehicle dynamics. Roll steer coefficient and roll centre height therefore need to be balanced for best all-round vehicle dynamics.

So which suspension is best?

Unfortunately the answer to this question is ‘it depends’. Sometimes, for example when undertaking a PBS assessment, a vehicle may perform better with a suspension that has a lower roll stiffness because the suspension has a higher roll centre or a lower roll steer coefficient. Further, the ranking of suspensions can change from one vehicle configuration to the next, and from one loading condition to the next, so it is rarely an open and shut case.

Published in Trailer magazine, Dec 2012 edition

Download PDF: Special-Report-Suspension-TM1212

Get more like this in your inbox

Subscribe to our Newsletter and never miss a post.